Kingdom of Saudi Arabia

The Kingdom of Saudi Arabia (المملكة العربية السعودية) is an Islamic absolute monarchy and the largest Arab nation in the Middle East. The Armed Forces of this nation comprise a number of conventional as well as non-conventional branches, the latter including the Saudi Arabia National Guard (SANG – essentially a private army loyal to the throne), the Saudi Royal Guard Regiment, Emergency Force (an anti-terrorism branch), the Saudi Special Forces (Thunder Forces), and the Border Guards and National Police Force. Some of these branches now have their own distinctive camouflage pattern.

Uniform Style

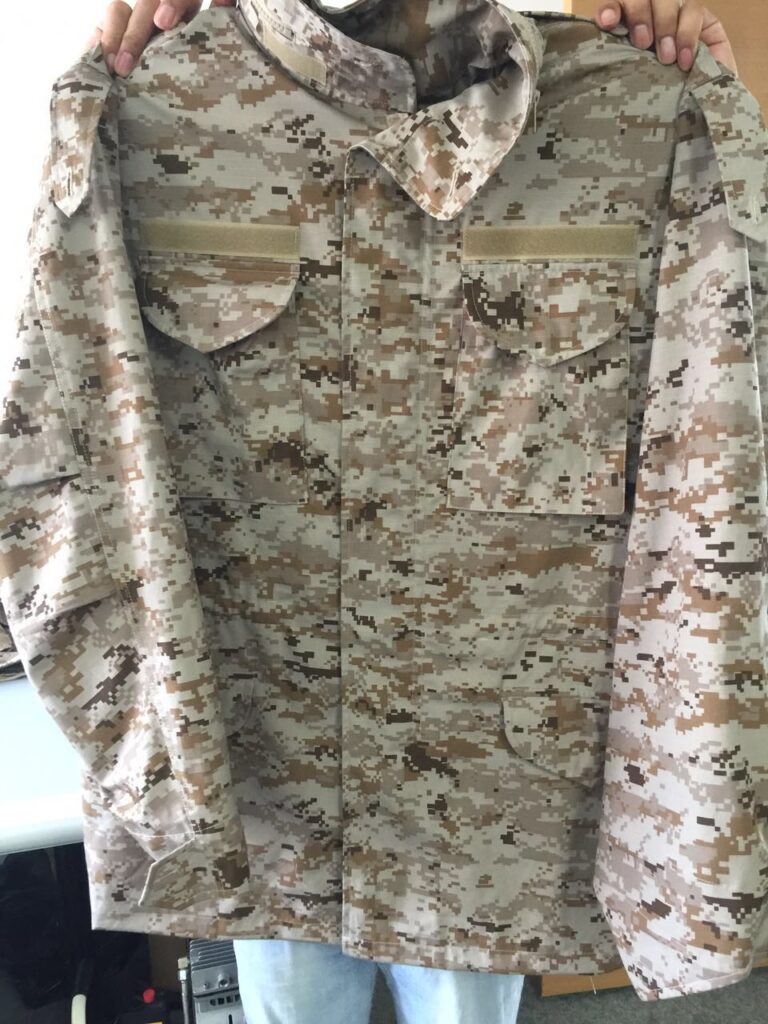

Influenced by the United States and the United Kingdom, Saudi Arabia also uses ACU, BDU, and M65 styles.

Pattern

Long supportive of Saudi Arabia through large military contracts, the United States has had a significant impact on the nation’s armed forces in terms of camouflage uniforms as well. Indeed, the United States supplied the Saudis with US-made uniforms for a number of years, from the same factories and contractors that produced them for the US government. Both olive green and m81 woodland camouflage uniforms made in the USA were worn by Saudi forces in the late 1980s, although both began being phased out in the early 1990s in favor of desert camouflage designs. The woodland design continued to be favored by Saudi Special Forces in the 1990s, however, as it set the unit apart from the rest of the Saudi Armed Forces.

Probably the longest-lived and most universally distributed camouflage pattern worn by the Saudi Armed Forces was a copy of the US-designed six-color “chocolate chip” desert pattern. This was introduced to Saudi units in the late early 1990s and continued well into the present period in one form or another. Several variants have been produced as well. Both US and Asian contract uniforms have been documented, varying slightly in terms of coloration and orientation of the screens, of which the images below are only a sample.

Material

Weight

- Min 203 g / m²

- Max 238 g / m²

- Tested method ASTM-D-3776

Yarns (min per cm)

- Warp (ends /cm) 41

- Fillings (picks / cm) 20

- Tested ASTM-D-3775)

Breaking Strength

- Warp – (min) – 86 kg

- Filling – (min) – 36 kg

- Tested ASTM-D-5034

Tearing Strength

- Warp (min) 3.2 kg

- Filling (min) 2.3 kg

- Tested ASTM-D-1424

Air Permeability (max)

- 5 (u.cm/sec/sq. cm) 5

- Tested ASTM-D-737

Fabric Appearance / Smoothness

- Initial 5 – Test AATCC143

- After 20 launderings 4.5 – AATCC 143 Table 11 3VAiii

- Test

Cotton Fiber Identification

- Combed Tested to AATCC-20 1

Nylon Identification

- Luster, denier absence of nylon waste tested to AATCC-20 1

Fibre Content

- Nylon / Cotton tested to AATCC-20A 1

Yarn Ply

- Visual 2

Weave

- Visual 1

Visual Shade Matching

- tested to AATCC Evaluation Procedure 9, Option A

- Presence of Labile Sulfur 1/

Colourfastness

- To Laundering (after 4 cycles) tested to AATCC 61 (test 3A 3/

- Perspiration (acid & alkaline) tested to AATCC 15

- Light (after 40 hours or 170 KJ) tested to AATCC-16 option 1 or 3 光照

- Crocking tested to AATCC-8

Dimensional Stability

- Test AATC96 VIX 4 /

PH

- Test AATCC81

Seam Efficiency

- Test ASTM-5034 5/

Oeko-Label for Cloth

Certificate of Oeko-Label for cloth or test report certified from the country of origin covering the tests specified in Oeko-Tex 100 & 200=. Showing fabric complies with environmental regulations p[rohit dangerous chemicals or dyes

Submit minimum of 4 meters (full width)

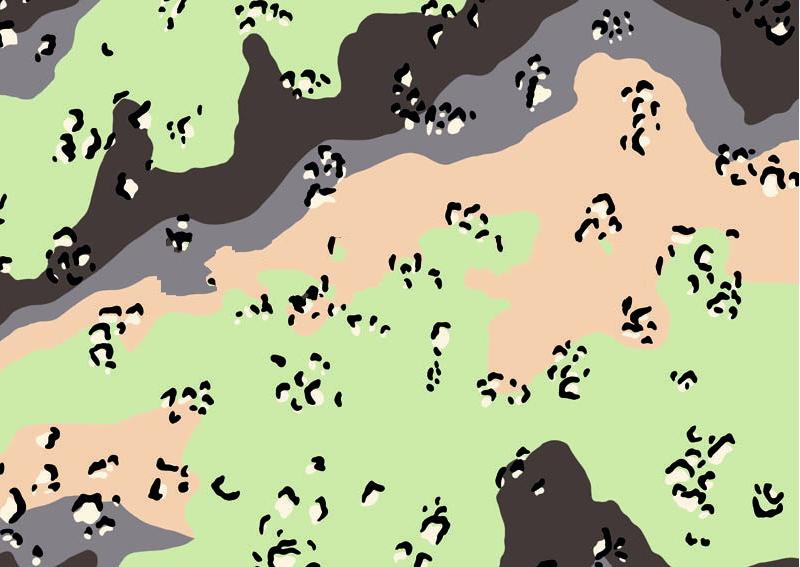

Illuminant D65

- Sand – L =60.27, a = 3.13 and b = 8.71

- Light Brown L = 54.33 – a = 4.36, b = 10.07

- Dark Golden L = 44.70, a = 6.82, b = 20.38

- Dark Brown – L = 32.59, a = 5.75, b = 13.34